How Facial Tissue Is Made: Manufacturing Process and Safety Standards?

I never thought about how facial tissue was made until I toured a paper mill. What seemed like a simple product actually follows a precise process with strict standards.

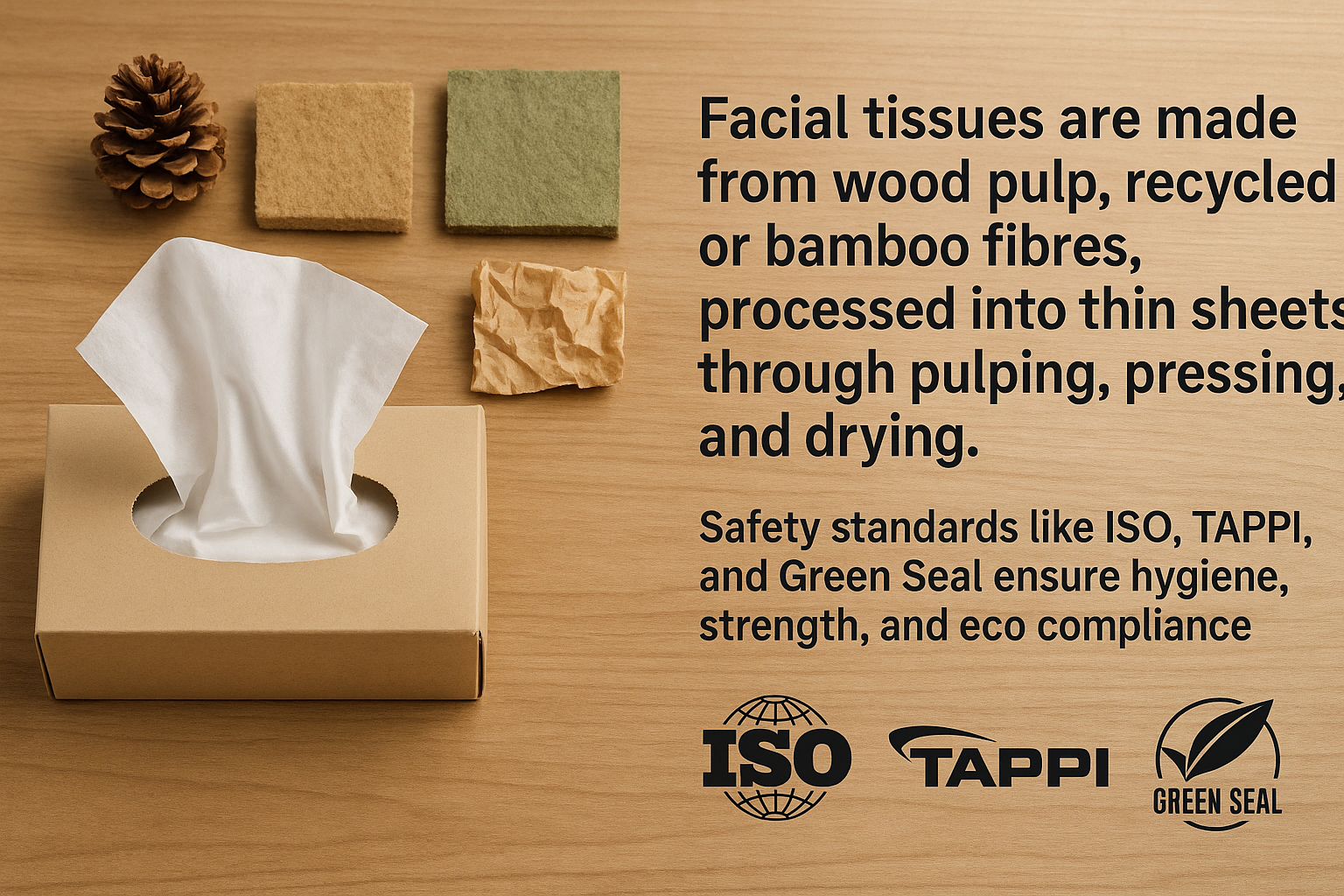

Facial tissues are made from wood pulp, recycled or bamboo fibers, processed into thin sheets through pulping, pressing, and drying. Safety standards like ISO, TAPPI, and Green Seal ensure hygiene, strength, and eco compliance.

Understanding the process and standards behind tissues shows why quality varies and why regulations protect both consumers and workers.

What is the raw material for tissue paper manufacturing?

The journey of facial tissue begins with pulp. Without good raw material, you don’t get good tissue.

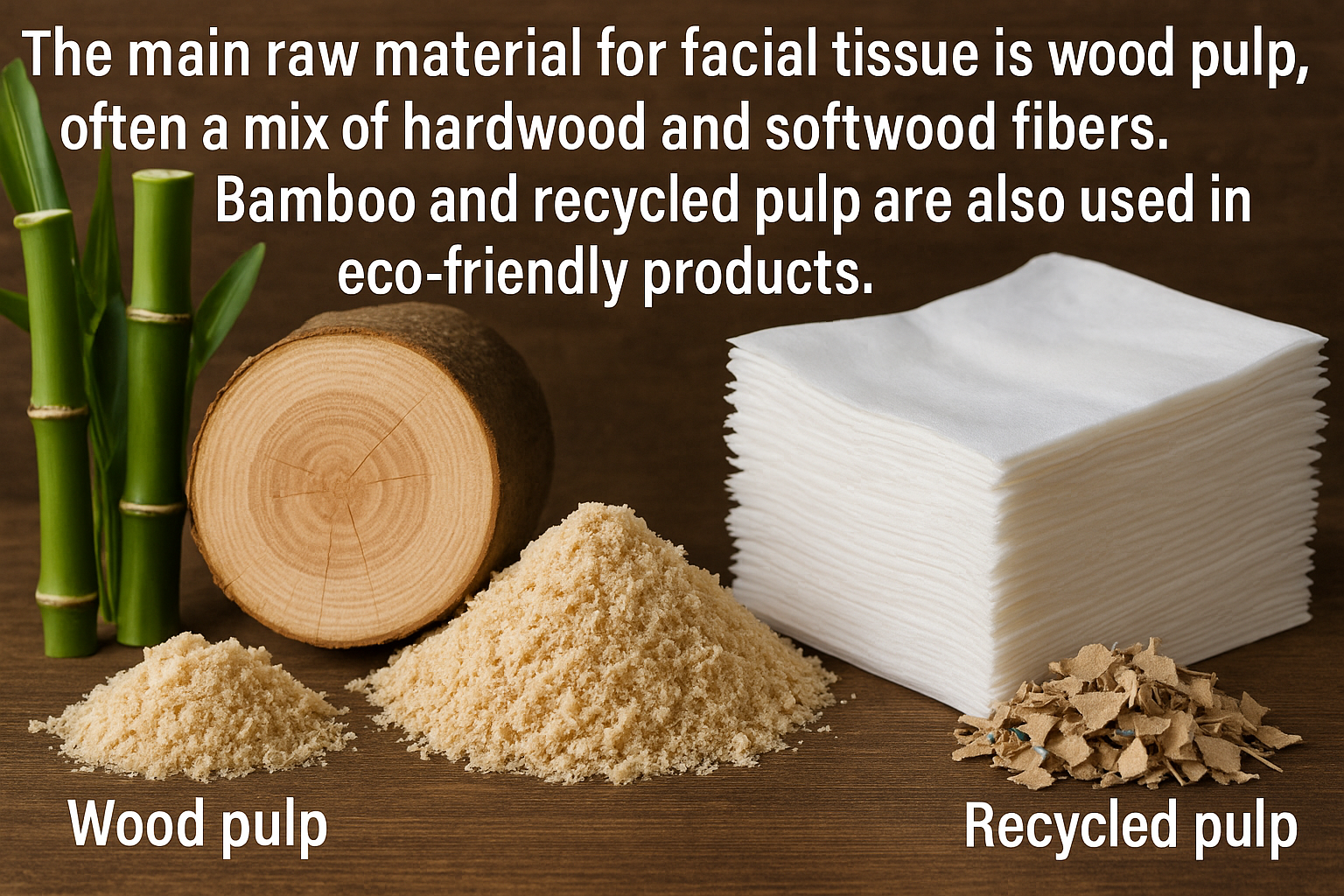

The main raw material for facial tissue is wood pulp, often a mix of hardwood and softwood fibers. Bamboo and recycled pulp are also used in eco-friendly products.

When I walked through a mill, I saw bales of pulp stacked like hay. Softwood pulp has long fibers that add strength, while hardwood pulp has shorter fibers that add smoothness. By blending them, manufacturers balance strength and softness.

In some factories, bamboo pulp is now replacing wood. It grows fast, is renewable, and works well for eco-conscious brands. Recycled pulp is another option, but it makes tissues stiffer and less consistent. Some producers mix recycled and virgin pulp to cut costs without losing too much comfort.

Additives are part of the recipe too. Binders improve wet strength. Softeners make the sheet gentle on skin. Some tissues even include aloe or lotion for premium products. What goes into the pulp directly shapes the tissue you hold in your hand.

How is facial tissue manufactured?

The process may look simple, but it combines heavy machinery, chemistry, and precision.

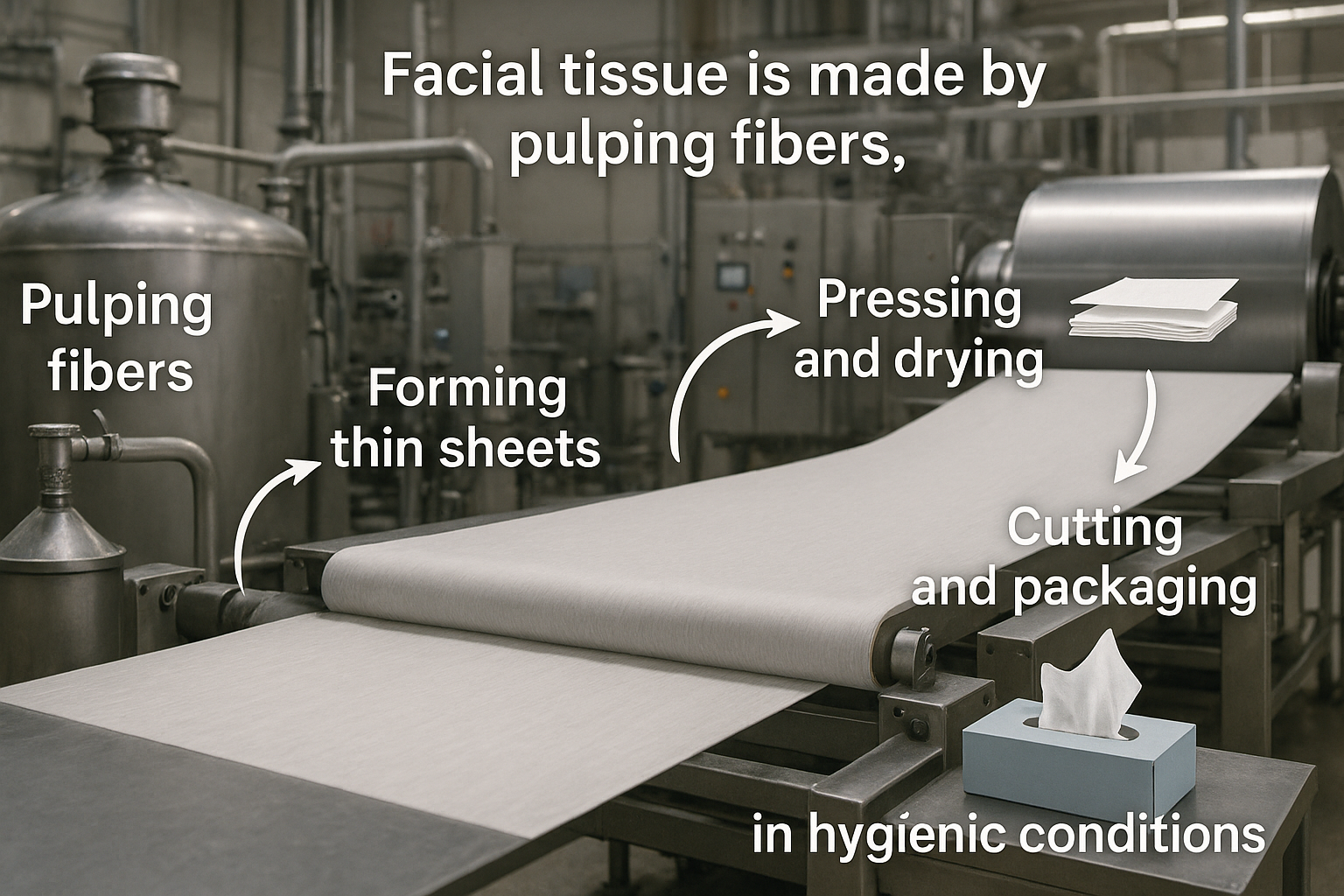

Facial tissue is made by pulping fibers, forming thin sheets, pressing and drying them, layering plies, and finally cutting and packaging them in hygienic conditions.

Here’s how I saw it broken down step by step:

- Pulping: Fibers are mixed with water and softened. Chemicals may be added to bleach or refine the pulp.

- Sheet Formation: The pulp slurry is spread onto wire screens, creating thin webs of fiber.

- Pressing and Drying: Excess water is pressed out, then sheets pass over heated cylinders to dry.

- Calendaring: Sheets are smoothed and thinned using rollers.

- Ply Bonding: Two or three plies are layered and lightly glued or embossed for strength.

- Cutting and Folding: Sheets are cut to size, folded, and stacked for boxes or rolled for pocket packs.

- Packaging: Final products are packed in boxes or plastic wraps in dust-free conditions.

The machines run continuously, producing thousands of sheets per minute. What impressed me most was how even the smallest flaw — a wrinkle, a tear — was automatically rejected by quality control scanners.

How to check the quality of tissue paper?

Not all tissues feel the same, and quality testing explains why. Standards help manufacturers measure performance.

The quality of facial tissue is checked by testing softness, absorbency, strength, and safety against chemical residues.

In labs, technicians test softness using panel evaluations or optical instruments. Absorbency is measured by how much water a sheet can hold before dripping. Strength tests include dry tensile strength and wet tensile strength. I even tried the “tear test” myself: pull a sheet gently from both ends and see how easily it rips. Premium tissues resist tearing even when damp.

Other tests look at linting — whether fibers shed on skin or surfaces. For sensitive users, hypoallergenic tests ensure there are no dyes or perfumes that could irritate. Reputable brands publish these results in white papers or certifications.

As a consumer, I notice the difference. A high-quality tissue feels silky, doesn’t shred when wet, and leaves no lint. Cheap tissues fail on at least one of these counts.

How to test the strength of facial tissue?

Strength may not seem important until you need a tissue during flu season. Weak tissues fall apart and spread germs.

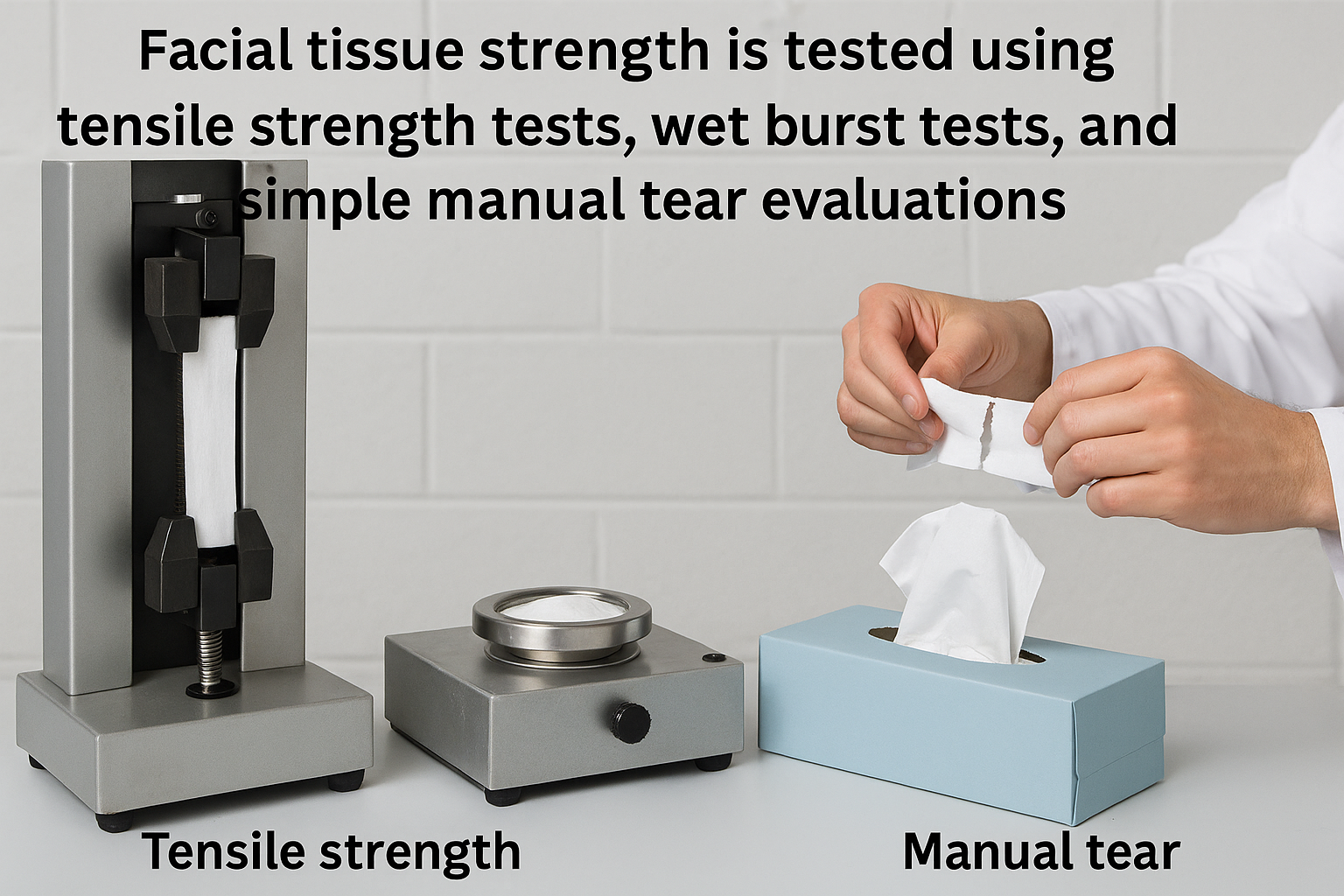

Facial tissue strength is tested using tensile strength tests, wet burst tests, and simple manual tear evaluations.

I once tried comparing tissues at home by soaking them in water. Premium ones stayed intact long enough to wipe a spill. Bargain ones dissolved instantly. That’s exactly what wet strength testing measures in labs. Machines pull or burst sheets under controlled stress to rate durability.

Dry strength is measured too. Stronger tissues hold together when used for wiping hands, small spills, or makeup smudges. Wet strength matters when sneezing or when moisture hits. Balance is key — tissues must stay intact in use but still break down after disposal.

Good standards make sure tissues are strong enough for daily use, but not so strong they harm plumbing or composting systems. It’s a delicate line between performance and disposability.

What safety standards apply to facial tissue?

Behind every box of tissue is a web of global safety and quality standards. These protect consumers, workers, and the environment.

Facial tissues follow standards like ISO for quality management, TAPPI for paper testing, Green Seal GS-1 for hygiene and sustainability, and GB/T 20808-2011 in China for chemical and safety limits.

I was surprised how many standards overlap. ISO 9001 ensures factories follow consistent quality systems. TAPPI provides methods for testing absorbency, softness, and strength. Green Seal GS-1 requires clean raw materials, safe workplaces, and eco-conscious production. In China, GB/T 20808-2011 sets limits on chemicals, dust, and hygiene in tissue production.

During my factory visit, safety rules were strict. Workers wore protective gear. Machines had guards and shut-off systems. Even packaging rooms had dust filters to keep tissues clean. These rules aren’t just paperwork — they make sure what reaches consumers is safe.

For procurement managers and regulators, these certifications are proof of reliability. For consumers, they’re the invisible shield ensuring each sheet is safe to use on skin.

Conclusion

Facial tissue is made through pulping, sheet formation, pressing, and packaging, with quality checked at every step. Global safety standards guarantee hygiene, comfort, and eco responsibility behind every box.

Share this article

About the Author

You might also like

Why Are Bamboo Fibre Tissue Manufacturers with Low MOQs Better Suited for Small and Medium-Sized Wholesalers?

Why Is Demand for Bamboo Fibre Toilet Paper Growing Rapidly in the US Market?

How to Determine Whether a Bamboo Fibre Tissue Manufacturer Possesses Long-Term Supply Capability?

Why Are Soft Pack Facial Tissues Gaining Popularity in Hotels and Restaurants?

How Can Customized Soft Pack Facial Tissues Boost Your Brand’s Image?

What Are the Key Benefits of Using Soft Pack Facial Tissues Over Traditional Boxed Tissues?

Is There a Market Demand for Eco-Friendly Soft Pack Facial Tissues in the Middle East?

What Should Wholesalers Look for in a Reliable Soft Pack Facial Tissue Manufacturer?

Can Soft Pack Facial Tissues Be Customized for Religious and Holiday Events?