How to Rapidly Assess Supplier Quality Using Bamboo Facial Tissue Samples?

Ordering from a new supplier is risky—especially in bulk. But with the right bamboo tissue sample test, you can spot poor quality early and avoid costly mistakes.

To evaluate bamboo tissue supplier quality, test samples for softness, GSM (thickness), strength, absorbency, and fiber purity. Examine packaging print clarity and certifications. A detailed bamboo tissue sample test helps verify material claims and ensures the manufacturer meets brand standards before placing a large order.

Let’s walk through how to test bamboo toilet paper quality using samples, and what signs indicate a supplier you can trust—or one you should avoid.

How do you test the quality of bamboo tissue paper?

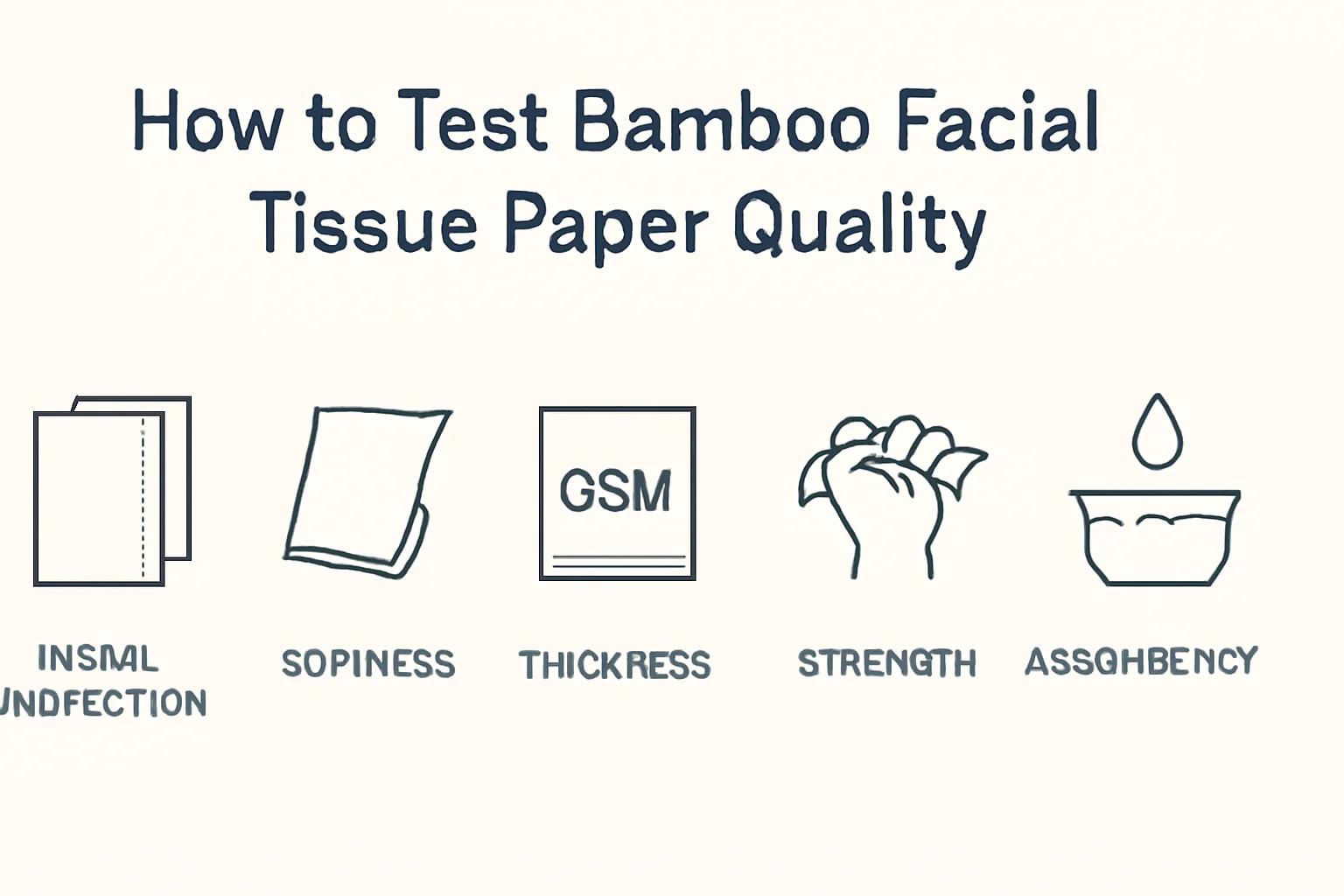

Sample testing doesn’t need a lab. You can perform basic checks in your office or showroom using standardized comparisons and tactile inspection.

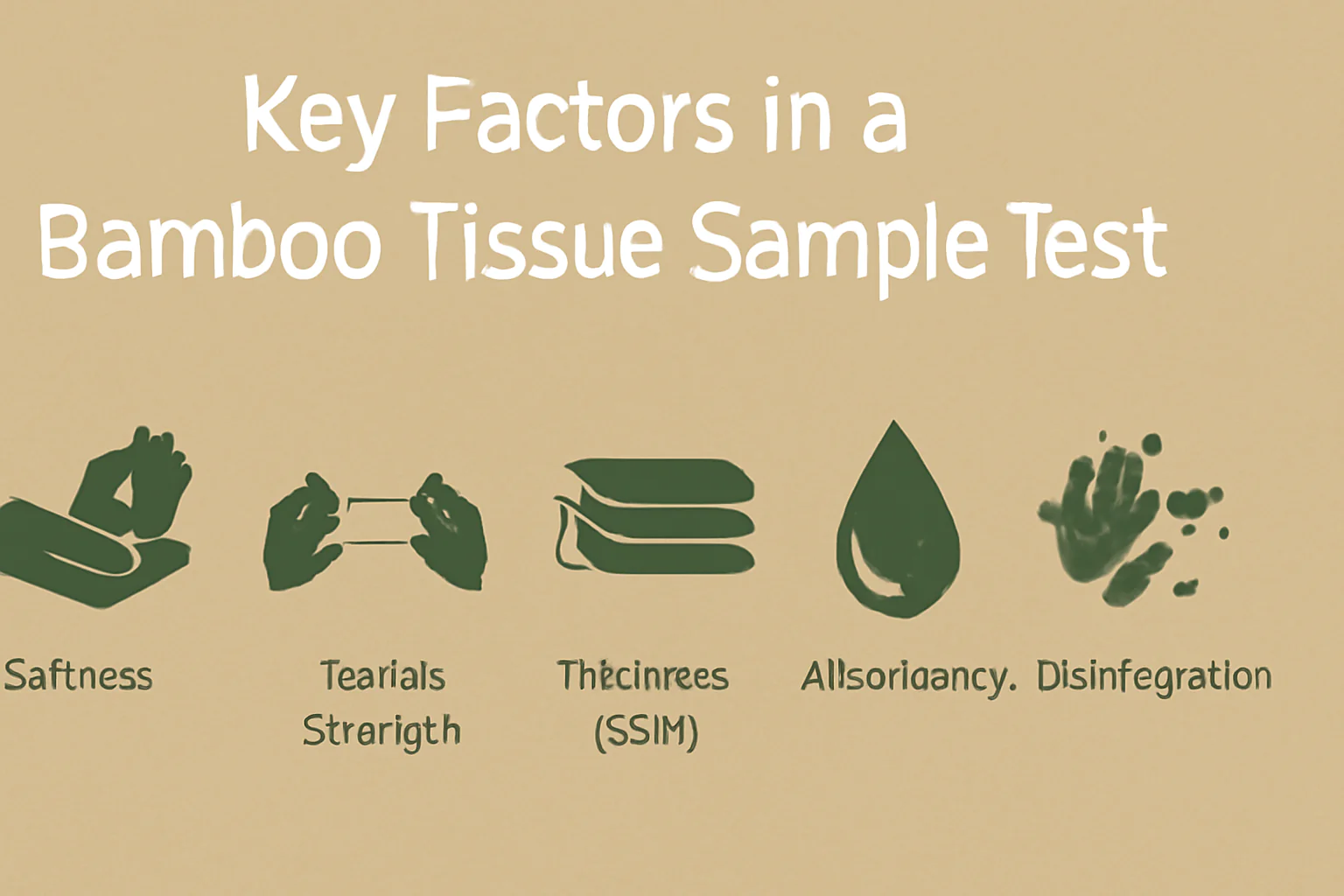

Key factors in a bamboo tissue sample test include softness, tensile strength, thickness (GSM), absorbency, and disintegration. Each reflects manufacturing consistency and raw material quality.

Easy Sample Testing Checklist

| Test Area | What to Check | How to Check It |

|---|---|---|

| Softness | Feel between fingers | Compare with leading retail brand |

| Thickness | Measure GSM (grams/m²) | Use micrometer or feel test |

| Absorbency | Drop test with 1 tsp water | Time absorption in seconds |

| Strength | Pull test | Stretch a dry sheet horizontally |

| Disintegration | Place in water and stir | Should dissolve within 30s–1min |

Take notes and photos of each test. Record results in a spreadsheet if comparing multiple suppliers.

What should you look for in bamboo facial tissue paper samples?

Beyond physical performance, visual cues reveal the manufacturer’s quality control standards. You want samples that look polished and feel premium.

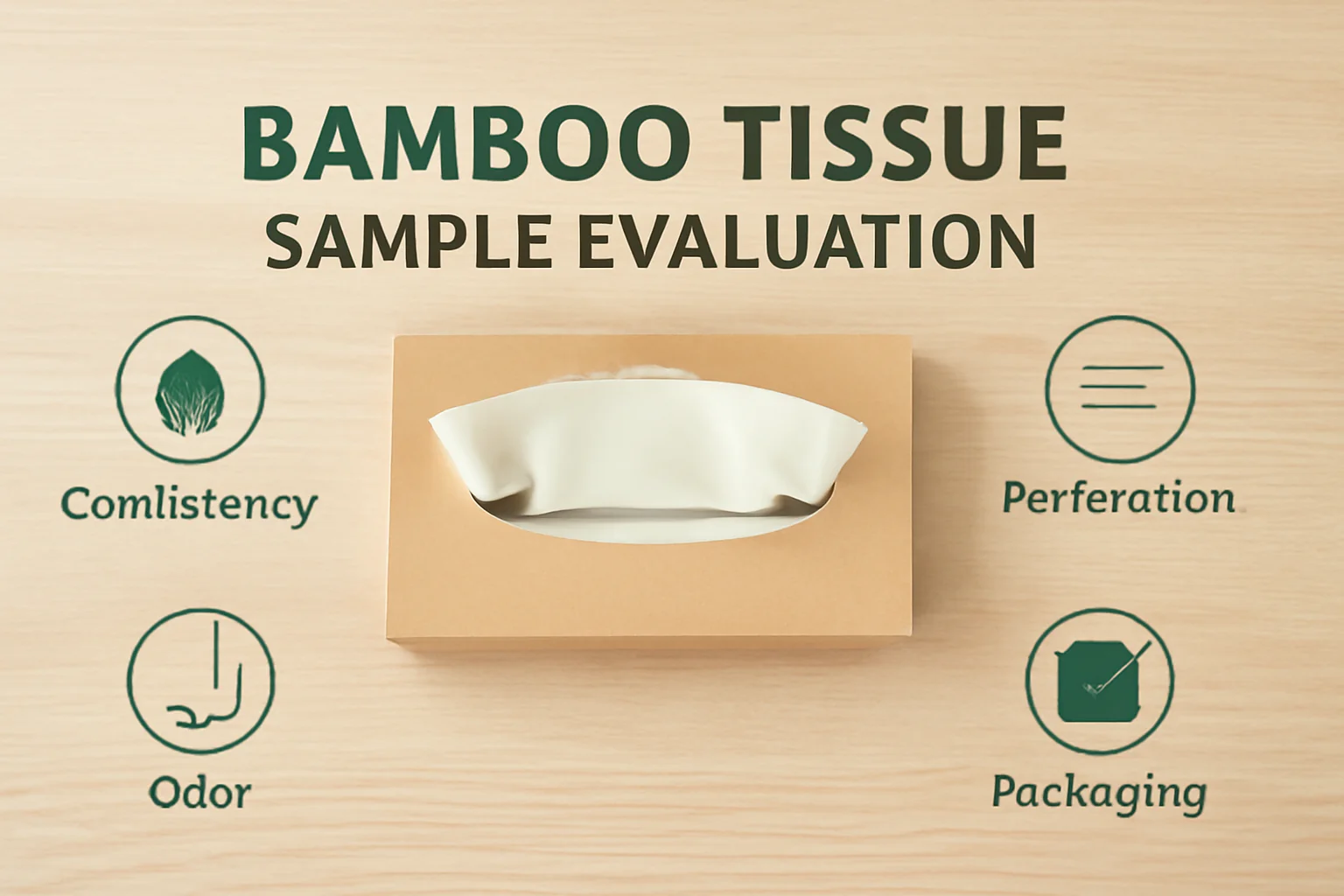

When you order bamboo tissue samples from manufacturer sources, check sheet consistency, perforation quality, odor, and packaging appearance.

Sample Quality Red Flags

| Feature | What It Suggests |

|---|---|

| Uneven sheet thickness | Inconsistent pulp blending |

| Loose rolls or tight cores | Poor machine calibration |

| Rough cut edges | Dull or misaligned blades |

| Strong odor | Chemical residue (bleach or softeners) |

| Flimsy outer packaging | Inadequate handling or low-grade wrap |

Good samples show investment in machinery, attention to detail, and real B2B readiness.

Is fiber purity important in bamboo tissue evaluation?

Yes. Many so-called “bamboo” tissues are actually mixed with wood pulp or recycled materials, especially in low-cost offerings.

Fiber purity is a core factor in determining quality. High-purity bamboo tissue is softer, stronger, and safer for sensitive skin. Mixed pulp often sacrifices performance.

How to Spot Real Bamboo

| Indicator | What to Look For |

|---|---|

| Label or spec sheet | 100% Bamboo / No wood pulp blends |

| Color tone | Slightly off-white (natural bamboo) |

| No bleach scent | Chemical-free processing preferred |

| Stretch when wet | Bamboo fiber holds up better |

Ask for a technical data sheet or material declaration if in doubt.

How do packaging and print quality affect supplier selection?

First impressions matter. Your brand will live on the shelf through packaging, so poor print or material finish is a deal-breaker.

When reviewing bamboo tissue samples, inspect the outer packaging: clarity of logos, color accuracy, fold alignment, and glue sealing quality all reflect the factory’s attention to detail.

Packaging Review Points

| Area | Why It Matters |

|---|---|

| Color match | Important for private label consistency |

| Material stiffness | Prevents collapse in shipping |

| Barcode readability | Retail compliance |

| Folding/glue seams | Protects tissue integrity |

| Multilingual layout | Needed for export to EU/MENA/US |

At Baoding Yibao, we provide full-color mockups and sample-printed outer packs to confirm packaging quality before bulk production.

What standards and certifications should be verified during sample review?

Certifications aren’t just paperwork—they show whether the factory follows sustainable, hygienic, and consistent processes.

Top manufacturers offer FSC, ISO, FDA, and GSO certificates. These should be available during the sample stage—ideally printed on the packaging or provided with the sample kit.

Ask for These During Sample Stage

| Certification | What It Proves |

|---|---|

| FSC | Bamboo sourced from responsibly managed farms |

| ISO 9001/14001 | Consistent production & environmental control |

| GSO | Gulf export compatibility |

| FDA | Skin-safe, non-toxic |

| SGS/Intertek | Lab-tested strength, thickness, safety |

If a supplier hesitates to show certs before contract signing, move on.

Conclusion

A strong supplier sends a strong sample. Use objective testing and visual inspection to qualify partners before placing volume orders. It’s fast, simple, and protects your brand.

Share this article

About the Author

You might also like

Why Are Bamboo Fibre Tissue Manufacturers with Low MOQs Better Suited for Small and Medium-Sized Wholesalers?

Why Is Demand for Bamboo Fibre Toilet Paper Growing Rapidly in the US Market?

How to Determine Whether a Bamboo Fibre Tissue Manufacturer Possesses Long-Term Supply Capability?

Why Are Soft Pack Facial Tissues Gaining Popularity in Hotels and Restaurants?

How Can Customized Soft Pack Facial Tissues Boost Your Brand’s Image?

What Are the Key Benefits of Using Soft Pack Facial Tissues Over Traditional Boxed Tissues?

Is There a Market Demand for Eco-Friendly Soft Pack Facial Tissues in the Middle East?

What Should Wholesalers Look for in a Reliable Soft Pack Facial Tissue Manufacturer?

Can Soft Pack Facial Tissues Be Customized for Religious and Holiday Events?