How to Reduce Costs Without Compromising Softness in Facial Tissue Procurement?

Import managers face pressure to cut expenses, but customers still demand soft, premium tissues. Cutting quality leads to lost sales and brand damage.

You can reduce procurement costs without losing softness by sourcing factory-direct, buying in bulk, optimizing ply count, and using OEM/ODM packaging. These methods lower expenses while protecting comfort.

[affordable soft tissues bulk](https://placehold.co/600x400](https://onepacktissue.com/wp-content/webp-express/webp-images/uploads/2025/09/BgSub_BgSub_clipboard-62.png.webp)

I have compared tissue suppliers across trade shows and RFQ platforms. The best strategies always save money without cutting softness. Let’s break them down.

What Strategies Help Reduce Tissue Procurement Costs Without Losing Softness?

Procurement managers often think savings mean lower quality. But smart sourcing shows otherwise.

Bulk sourcing, supplier consolidation, and strategic ply optimization reduce tissue costs while keeping comfort and softness intact.

Let's explore more

The first way to save is bulk buying. Larger container orders reduce per-unit costs. Many factories in China and Southeast Asia offer deep discounts once you cross one or two container volumes.

Supplier consolidation also cuts costs. Instead of ordering from three small suppliers, managing one reliable supplier simplifies logistics and saves on shipping. I worked with a retailer in Kuwait who reduced expenses by 12% just by switching to one consolidated supplier.

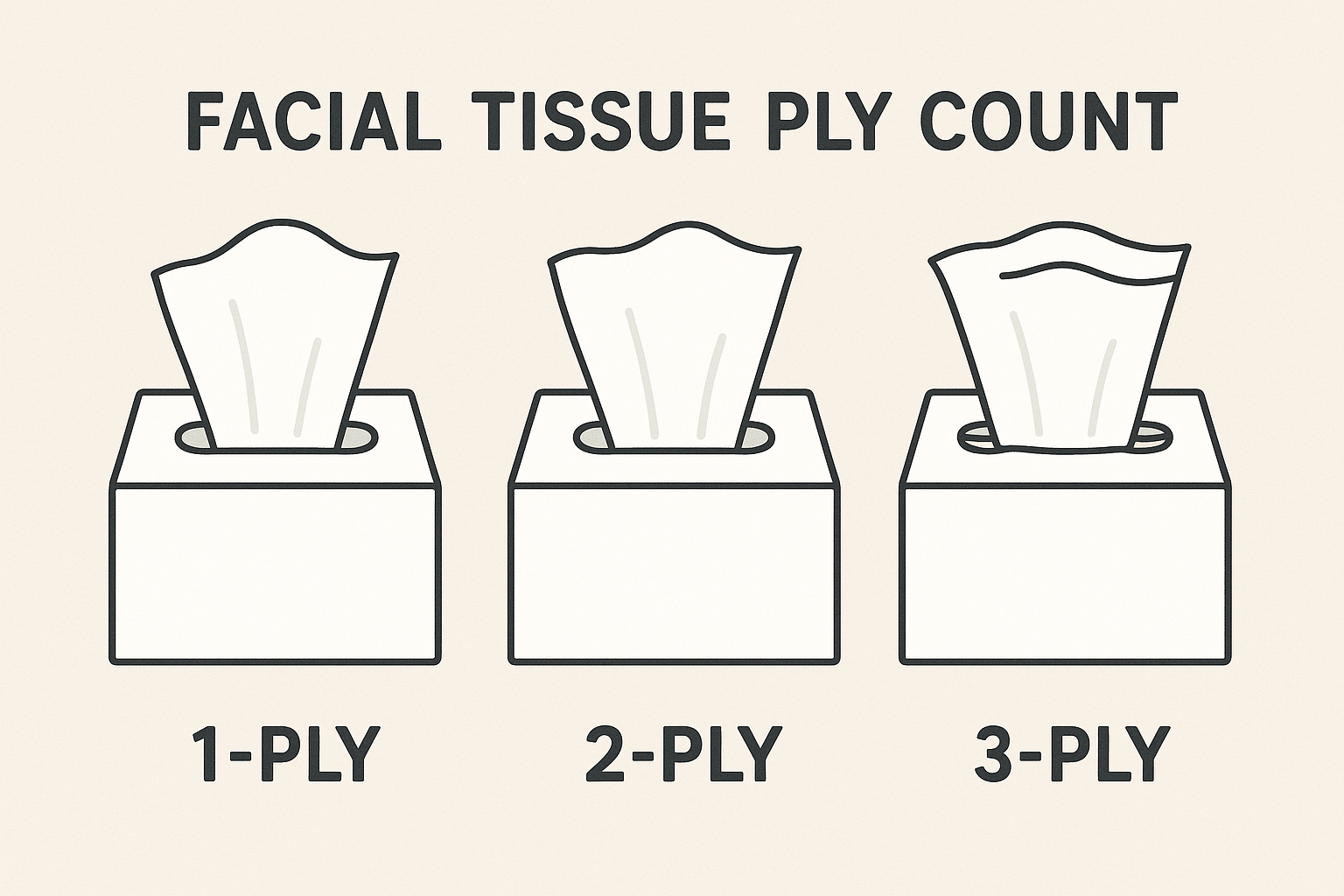

Finally, ply optimization plays a role. Customers expect 3-ply for premium lines, but in budget categories, 2-ply is acceptable. Creating a dual product line—basic 2-ply and premium 3-ply—gives flexibility without losing softness in your top-selling products.

These approaches prove that cost control doesn’t have to mean product compromise.

Why Is Direct Factory Sourcing Effective for Tissue Buyers?

Middlemen increase prices and reduce flexibility. Going straight to factories solves both issues.

Direct factory sourcing gives import managers better pricing, faster customization, and control over product specifications.

Let's explore more

When you buy through distributors, every step adds margin. A direct link to manufacturers eliminates these extra costs. This is especially true in tissue procurement, where margins are slim and volumes are high.

Factories also allow more flexibility. Import managers can request custom ply counts, sheet sizes, and packaging formats that distributors may not support. In one case, I worked with a Saudi buyer who wanted Arabic-English bilingual packaging. The factory delivered this directly, while distributors offered only generic stock.

Factory-direct sourcing also improves transparency. Buyers can request samples, inspect certifications like ISO or SGS, and test products before placing orders. This reduces risk and ensures that softness and quality remain intact.

It may take more negotiation at the start, but in the long run, factory-direct sourcing provides the best balance of price and quality.

How Does Ply Count Optimization Cut Costs in Facial Tissue Supply?

Not every tissue needs to be the same. Ply count can be adjusted to balance value and comfort.

Using 2-ply for budget lines and 3-ply for premium lines reduces costs while keeping softness in the right categories.

Let's explore more

Ply refers to how many layers of paper are pressed together. More plies mean greater softness and strength, but also higher cost.

Most retailers in the Middle East stock both 2-ply and 3-ply tissues. The 2-ply serves price-sensitive customers, while the 3-ply serves premium shoppers. This tiered approach ensures that every market segment is covered.

During a supermarket audit in Doha, I observed that 2-ply boxes often outsold 3-ply by volume, but 3-ply generated higher margins per unit. This shows how ply optimization directly affects profitability.

Import managers can also work with factories to test hybrid solutions, such as compact 3-ply packs that reduce material use. With smart product design, ply optimization keeps both budgets and customers satisfied.

What Role Does OEM/ODM Packaging Play in Cost Savings?

Packaging is more than branding—it is also a cost control tool.

OEM/ODM packaging lets buyers customize branding while controlling expenses through factory-optimized formats and bulk runs.

Let's explore more

Factories often offer OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services. This means procurement teams can design their own packaging without building new production lines.

Custom packaging gives control over printing, language, and design. It also eliminates the need for third-party packaging services, which often add unnecessary costs. At a trade fair in Guangzhou, I saw how many buyers switched to OEM packaging to save up to 15% compared to outsourcing design locally.

By combining OEM packaging with private label strategies, retailers in the Gulf often build brand loyalty while saving money. For example, a UAE supermarket chain sourced factory-direct tissues with bilingual logo packaging. They sold at competitive prices while reinforcing brand identity.

OEM/ODM is a win-win: branding power plus cost savings.

How Can Procurement Managers Use RFQ Platforms and Comparison Sourcing?

The right sourcing tools turn negotiation power into cost savings.

RFQ platforms and supplier comparison sites help import managers secure competitive pricing without lowering softness or specifications.

Let's explore more

RFQ (Request for Quotation) platforms like Alibaba, Made-in-China, or Globalsources allow buyers to post exact requirements and invite bids from multiple suppliers. This competition forces suppliers to sharpen their prices.

Comparison sourcing is equally powerful. Import managers can request samples from three to five factories and test them side by side. In one case, a distributor in Egypt saved 18% on tissue procurement by switching to a new supplier after a simple RFQ round.

These tools also reduce risk. Buyers can filter suppliers by certifications (ISO, SGS, FDA) and shipping records. This ensures that savings come without quality loss.

For procurement teams, regular use of RFQ platforms and sourcing comparisons should be a standard habit. It keeps suppliers competitive and protects margins without sacrificing softness.

Conclusion

Cost savings in tissue procurement come from strategy, not compromise. With bulk buying, factory sourcing, ply optimization, OEM packaging, and RFQ tools, managers cut costs while keeping products soft.

Share this article

About the Author

You might also like

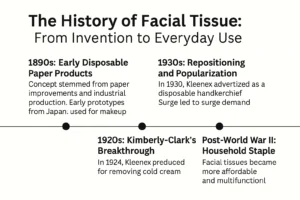

The History of Facial Tissue: From Invention to Everyday Use?

What Is Facial Tissue and How Is It Different From Toilet Paper?

Is Bamboo Pulp a Better Option for Soft Facial Tissue Buyers?

What Packaging Options Are Available for Soft Facial Tissues in the Food Service Industry?

Why Is Softness the Top Priority in Facial Tissue Selection?

How to Choose the Right Soft Facial Tissue for Middle Eastern Markets?

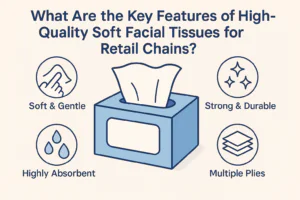

What Are the Key Features of High-Quality Soft Facial Tissues for Retail Chains?

How Can Customized Soft Facial Tissue Packaging Elevate Your Brand?

Why Do Wholesalers Prefer Soft Facial Tissues Made from Virgin Pulp?