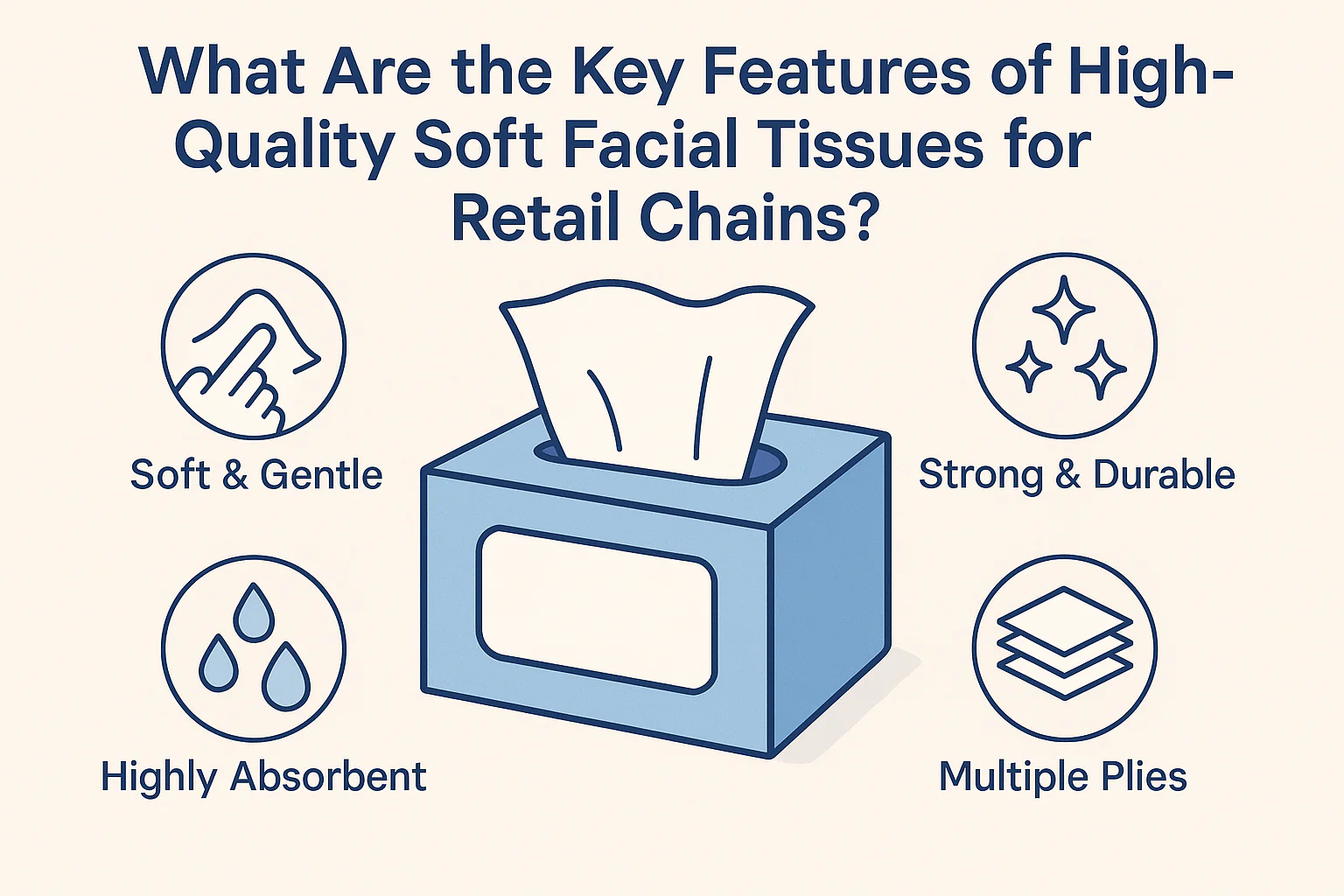

What Are the Key Features of High-Quality Soft Facial Tissues for Retail Chains?

Shoppers notice the smallest details in daily essentials. Rough or weak tissues can harm customer loyalty and damage a retailer’s brand image.

High-quality facial tissues combine layered softness, strong absorbency, and hygienic production. They are usually 3-ply, made with virgin or bamboo pulp, and designed with shelf-ready packaging that attracts customers in supermarkets.

Retail buyers know that consistency matters. The tissue a customer uses once shapes their opinion of the store’s product range. Let’s look deeper at what makes a tissue high quality.

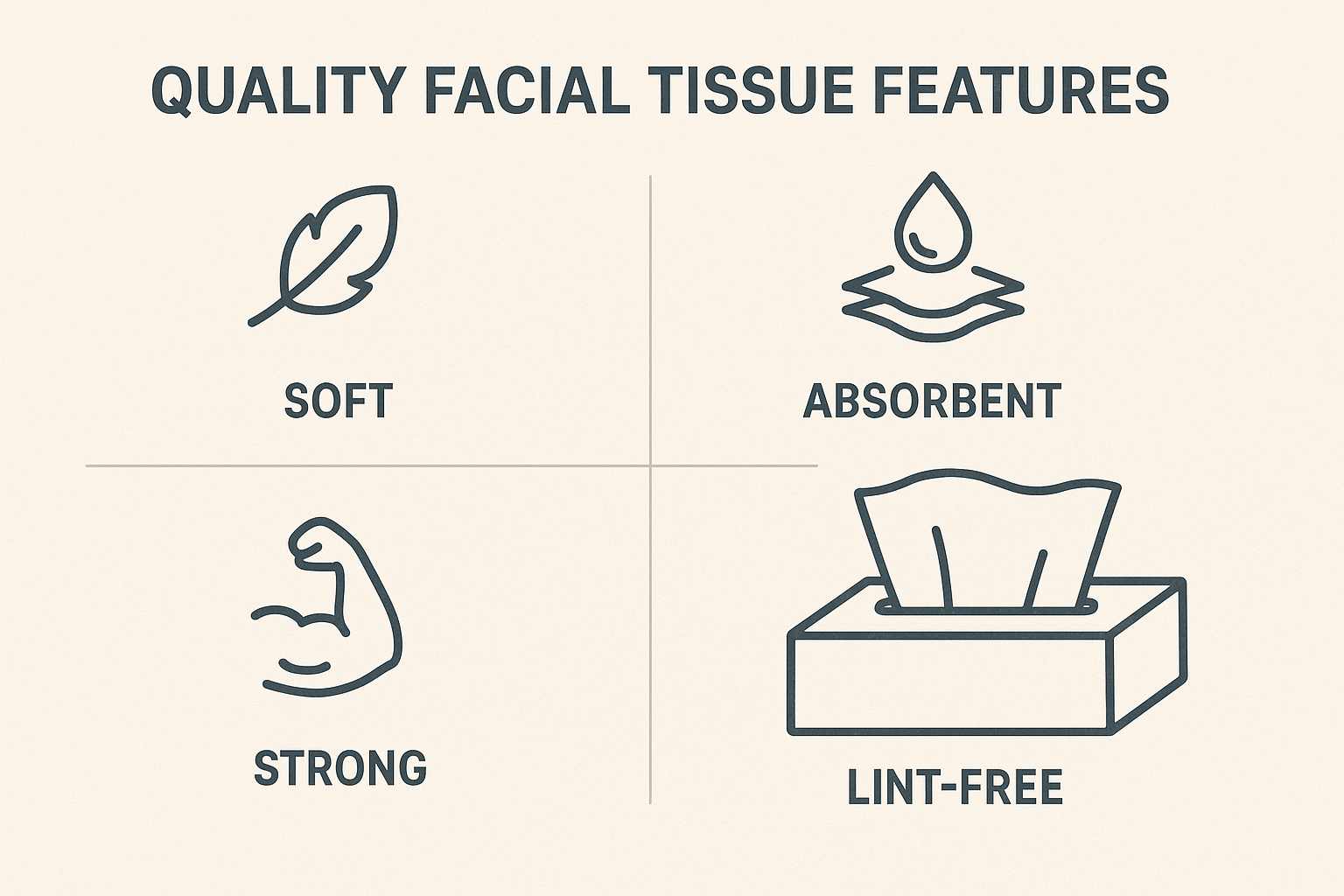

What Makes a Facial Tissue High Quality?

Customers expect soft tissues that don’t tear in use. Poor tissues frustrate shoppers and reduce brand loyalty.

A high-quality tissue must balance softness, strength, and absorbency. The right mix ensures comfort while keeping usage efficient.

Let's explore more

High-quality tissues come from strong raw materials like 100% virgin wood pulp or bamboo pulp. These fibers make tissues feel smooth while staying durable. When a customer uses a tissue on sensitive skin, they expect comfort. If the paper feels rough, it fails the quality test.

Retailers also need absorbency. A good tissue soaks up moisture quickly without breaking apart. Customers will notice if they need multiple sheets for one use. Strong absorbency reduces waste and improves value perception.

Softness is another key measure. Layers of tissue—usually 2-ply or 3-ply—create comfort. The ply count also signals quality on packaging. In my own experience with supplier trials, I found that tissues marketed as premium always met the 3-ply standard.

Retail chains that stock high-quality tissues signal care for their shoppers. This detail can increase return visits and long-term loyalty.

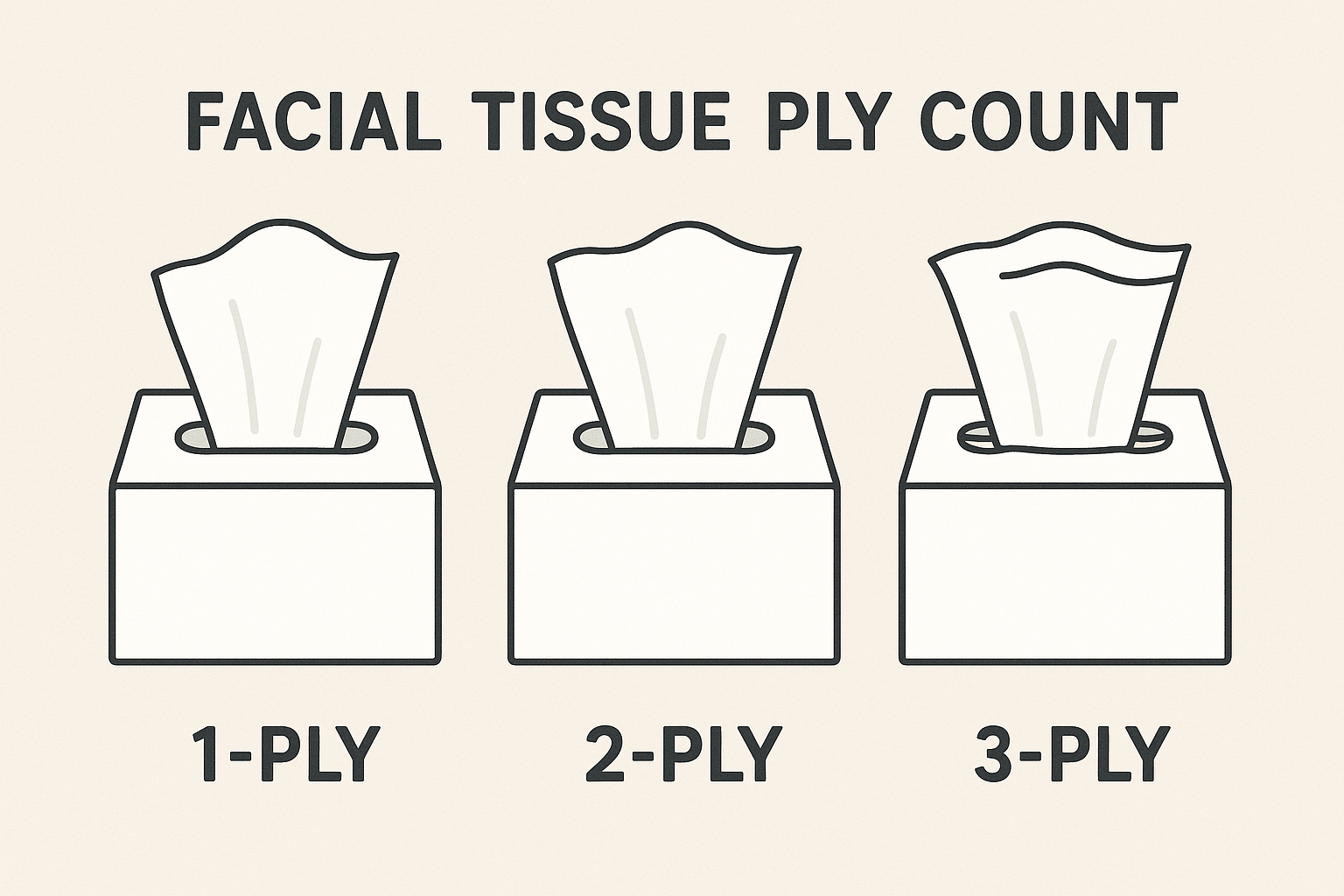

Why Is Ply Count Important for Retail Tissues?

Shoppers often check ply count on the box before buying. This small number communicates a lot about quality.

Ply count reflects comfort and durability. A 3-ply tissue is the retail standard for premium quality, offering softness and strength in one product.

Let's explore more

Each ply is a layer of paper pressed together. Single-ply tissues are thin and may tear easily. Two-ply tissues add strength, but the real difference comes with three-ply tissues. These feel luxurious and can handle repeated use without tearing.

Retailers need to think of customer psychology. A shopper scanning shelves sees “3-ply” as a guarantee of comfort. This labeling builds trust before the box is even opened. In competitive retail spaces, the number on the box helps one product stand out.

I remember watching a shopper in a supermarket aisle in Dubai. She picked up two brands and compared only the ply count. She chose the 3-ply pack even though it cost more. This is proof that ply is a decision driver.

For purchasing managers, stocking 3-ply products ensures higher satisfaction rates. Even if costs are higher, the long-term return is greater customer loyalty.

How Does Absorbency Affect Customer Satisfaction?

Shoppers value tissues that do the job in one sheet. Poor absorbency leads to frustration and waste.

Absorbent tissues work faster, reduce the number of sheets needed, and give shoppers a sense of good value.

Let's explore more

Absorbency depends on fiber type and production method. Virgin pulp absorbs moisture more evenly than recycled fibers. Bamboo pulp also offers strong absorbency and appeals to eco-conscious customers.

When tissues break apart in use, customers get annoyed. I tested this once during a supplier trial. A tissue fell apart after one wipe, and it made me think the brand was cheap. Retail buyers must avoid this experience for their customers.

Better absorbency also reduces waste. A customer using two sheets instead of four feels they got better value. This perception links directly to loyalty. Retail chains that sell absorbent tissues can market them as efficient and cost-saving.

Absorbency also matters in specific markets. In the Gulf, where climate is dry and dust is common, tissues get heavy daily use. Strong absorbency is not optional—it’s expected.

What Role Does Packaging Play in Supermarket Tissue Sales?

Customers buy with their eyes before they test the product. Packaging is the silent salesman on the shelf.

Shelf-ready packaging with clear labeling, attractive design, and easy storage drives sales and builds brand recognition in retail environments.

Let's explore more

Packaging serves two functions: protection and marketing. It keeps tissues clean and ready for use, but it also tells the customer about the brand. Colors, ply count, and language matter. In Middle Eastern markets, bilingual Arabic-English packaging is not optional. It’s essential for clarity and trust.

Retail-ready packaging also influences logistics. Boxes must stack neatly, open easily, and display branding clearly. I once saw a retail audit in Jeddah where poorly stacked tissue boxes collapsed on the shelf. This not only looked bad but also reduced sales. Good packaging avoids this.

Eco-friendly designs are another trend. Shoppers notice if packaging highlights recyclability or reduced plastic. Retailers who offer sustainable packaging gain a stronger brand image.

Packaging is a long-term branding investment. Even if the tissue is high quality, poor packaging will lower sales.

Which Tissue Materials Are Best for Sensitive Skin?

Customers with allergies or sensitive skin judge tissue quality carefully. Material choice makes a clear difference.

The best tissues for sensitive skin use 100% virgin pulp or bamboo pulp, which produce smooth, soft, and safe sheets.

Let's explore more

Virgin pulp comes from fresh fibers with no previous processing. This purity ensures fewer dust particles and more softness. Bamboo pulp has natural hypoallergenic qualities, making it another strong option. Both are ideal for sensitive skin, unlike some recycled pulp products that may feel rough.

Sensitive customers often complain about tissues that cause redness or irritation. This is common when tissues contain dust or harsh fibers. During a supplier consultation, I once compared virgin pulp tissue with mixed recycled tissue. The virgin pulp sample was smooth and strong. The recycled version shed dust and felt rough.

Retailers must consider these differences. Stocking soft tissues for sensitive skin builds trust with families, especially mothers buying for children. Highlighting “skin safe” or “hypoallergenic” on packaging reassures customers and strengthens brand loyalty.

In markets like Saudi Arabia and the UAE, premium customers expect this level of care.

Conclusion

High-quality facial tissues for retail chains must be soft, absorbent, hygienic, and attractively packaged. Meeting these benchmarks keeps customers loyal and strengthens supermarket brand trust.

Share this article

About the Author

You might also like

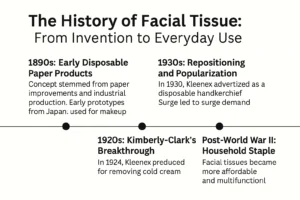

The History of Facial Tissue: From Invention to Everyday Use?

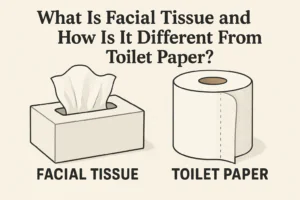

What Is Facial Tissue and How Is It Different From Toilet Paper?

How to Reduce Costs Without Compromising Softness in Facial Tissue Procurement?

Is Bamboo Pulp a Better Option for Soft Facial Tissue Buyers?

What Packaging Options Are Available for Soft Facial Tissues in the Food Service Industry?

Why Is Softness the Top Priority in Facial Tissue Selection?

How to Choose the Right Soft Facial Tissue for Middle Eastern Markets?

How Can Customized Soft Facial Tissue Packaging Elevate Your Brand?

Why Do Wholesalers Prefer Soft Facial Tissues Made from Virgin Pulp?