What Materials Are Used to Make Facial Tissue? A Guide to Pulp Types?

I used to assume all tissues were just “paper.” But when I started looking into how they’re made, I discovered a whole world of different pulp types with unique strengths.

Facial tissues are mainly made from wood pulp, recycled fiber, or bamboo pulp. Each material affects softness, strength, cost, and sustainability, shaping both comfort and environmental impact.

Knowing the difference between pulp types helps buyers, manufacturers, and consumers make better choices for hygiene, comfort, and sustainability.

What is facial tissue paper?

When I pick up a box of tissues, I don’t usually think about the process behind it. But “facial tissue” has a specific meaning in the paper industry.

Facial tissue paper is a thin, soft, disposable paper designed for wiping the face or nose, usually made from 14–18 g/m² pulp with additives for softness and strength.

The light weight of facial tissue makes it different from napkins or towels. It’s manufactured under hygienic conditions and is often treated to feel smooth and gentle on skin. Manufacturers may add binders so the sheets hold together when wet, or softeners to avoid friction against the nose.

I’ve noticed the difference when using bargain tissues compared to premium ones. The cheap ones tear instantly with moisture. The better ones stay intact, which means they use stronger fibers or blend in additives. From a technical perspective, facial tissues are all about balancing absorbency and softness without sacrificing disposability.

Wood pulp: the most common choice

Most tissues you see in stores are made from virgin wood pulp. It’s cheap, available worldwide, and easy to process.

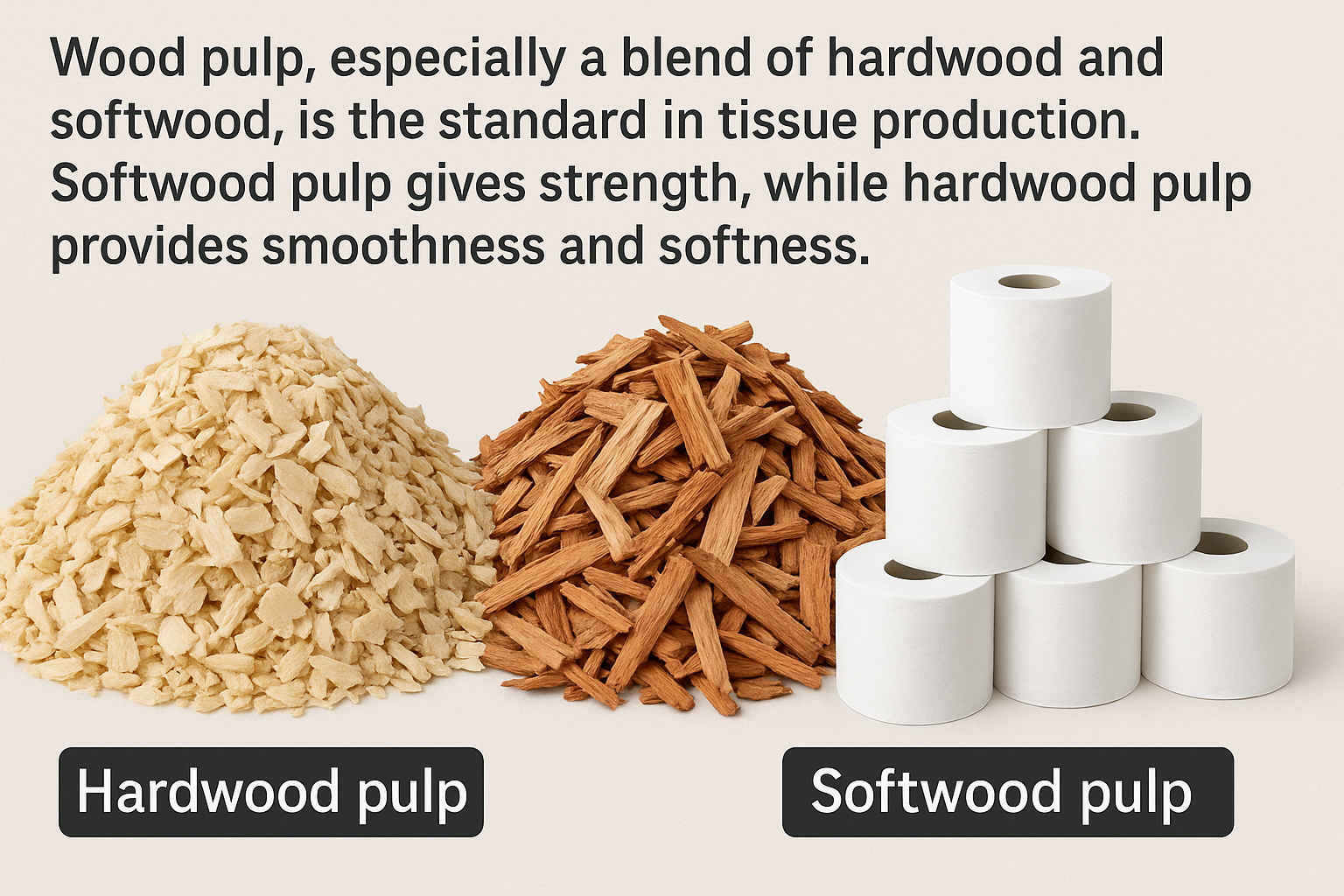

Wood pulp, especially a blend of hardwood and softwood, is the standard in tissue production. Softwood pulp gives strength, while hardwood pulp provides smoothness and softness.

When I visited a pulp mill, I learned that softwood fibers are longer, which helps tissues stay intact when damp. Hardwood fibers are shorter, which makes tissues feel smoother. By mixing both, manufacturers get a product that feels soft but doesn’t fall apart in your hands.

Virgin pulp has another advantage: consistency. Recycled fibers vary in quality, while fresh wood pulp allows producers to control texture and absorbency. This is why many top brands highlight “100% virgin pulp” on their packaging.

The downside, of course, is sustainability. Virgin wood pulp requires cutting down trees. Brands that care about their image often use FSC-certified pulp to show the wood is sourced from responsibly managed forests. From my perspective as a consumer, I feel better buying FSC-labeled boxes, even if they cost a little more.

Recycled pulp: cost-effective but variable

Some brands use recycled pulp to lower costs and reduce environmental footprint. This pulp is made by reprocessing used paper and fibers.

Recycled pulp tissues are cheaper and eco-friendlier but can be less soft, less consistent, and sometimes contain residual chemicals from prior use.

I once tried a box of recycled-pulp tissues because I wanted a greener option. The difference was clear: they felt stiffer, and my skin started to itch after repeated use. Later I found out that recycled pulp can carry small traces of ink or chemicals, even though it’s cleaned and processed before becoming tissue.

From a technical side, recycled fibers are shorter because they’ve already been broken down once. Short fibers don’t bond as well, making the tissue weaker. To compensate, producers may add binders or mix in some virgin pulp for stability.

Still, recycled pulp has its place. For industrial or bulk settings where comfort is less important, it works well. Environmentally, it reduces demand for virgin fiber. But for sensitive skin or premium home use, recycled pulp doesn’t always deliver the comfort I expect.

Bamboo pulp: the eco-friendly challenger

In recent years, bamboo has entered the tissue market as a sustainable alternative. I first saw bamboo tissues in a health store, labeled “tree-free.”

Bamboo pulp tissues are eco-friendly, biodegradable, and naturally antibacterial, making them popular among green-conscious buyers despite being pricier than regular tissues.

Bamboo grows much faster than trees — some species reach maturity in 3–5 years compared to decades for hardwood. That makes it a renewable source. The pulp fibers are long, giving tissues natural strength, and the texture feels smooth without needing too many additives.

I tried bamboo tissues for a month, and while they were slightly firmer than softwood-based tissues, they didn’t irritate my skin. In fact, they felt clean and crisp. The price was higher, though. A single pack cost nearly double my regular brand.

On the industrial side, bamboo pulp requires different processing equipment. But as demand grows, more factories are adapting. For eco-conscious consumers and sustainable brands, bamboo is quickly becoming the material of choice.

Other additives in tissue manufacture

Beyond pulp, tissues often contain additives that change how they feel or perform. I noticed this the first time I used “lotion tissues.”

Additives like lotions, aloe, perfumes, or wet-strength binders are used to improve comfort, absorbency, or durability in facial tissues.

Lotion-infused tissues help prevent red, sore noses during allergy season. Aloe or vitamin E is added for soothing. Some “anti-viral” tissues even include chemical treatments that claim to reduce virus survival on the paper.

Binders make tissues hold up better when wet, which is useful but can slow down biodegradability. Perfumes and dyes give a pleasant scent or appearance, but I avoid them because they irritate my skin.

From an engineering perspective, additives are about performance and branding. From a consumer perspective, they’re about comfort and experience. Understanding what’s in your tissue helps you choose between pure, eco-friendly options and enhanced, comfort-focused ones.

Conclusion

Facial tissues are more than “just paper.” They’re crafted from wood pulp, recycled pulp, or bamboo, with additives shaping softness and strength. Each material affects comfort, cost, and sustainability — making pulp choice a key factor in quality.

Share this article

About the Author

You might also like

Why Are Bamboo Fibre Tissue Manufacturers with Low MOQs Better Suited for Small and Medium-Sized Wholesalers?

Why Is Demand for Bamboo Fibre Toilet Paper Growing Rapidly in the US Market?

How to Determine Whether a Bamboo Fibre Tissue Manufacturer Possesses Long-Term Supply Capability?

Why Are Soft Pack Facial Tissues Gaining Popularity in Hotels and Restaurants?

How Can Customized Soft Pack Facial Tissues Boost Your Brand’s Image?

What Are the Key Benefits of Using Soft Pack Facial Tissues Over Traditional Boxed Tissues?

Is There a Market Demand for Eco-Friendly Soft Pack Facial Tissues in the Middle East?

What Should Wholesalers Look for in a Reliable Soft Pack Facial Tissue Manufacturer?

Can Soft Pack Facial Tissues Be Customized for Religious and Holiday Events?